Tungsten Target Working Principle

The raw material of tungsten target is tungsten powder, whose common types are arc target type, planar target type and rotary target type.

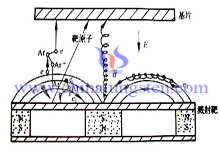

Sputtering: When the positive ions accelerated by the electric field (hereinafter called energetic particles), it will bombard the target surface, these energetic particles will exchange energy with the molecules and atoms on the target surface, and then these atoms will sputtering out from the target surface.

Vacuum sputtering coating (sputtering film deposition): because atoms sputtered out own a certain kinetic energy, they can return to the target surface and form a thin film, this process is known as vacuum sputtering coating.

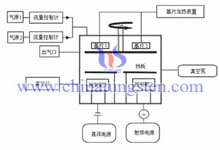

Tungsten target working principle:

In a high vacuum chamber (10-3-10-4Pa), adding an orthogonal magnetic and electric field between the cathode (the sputtered target electrode) and the anode, and then fill it with an inert gas (argon gas). On the surface of the target material, permanent magnet will generate a magnetic field, which will compose a crossed electric and magnetic field with high voltage electric field. Argon gas in the electric field will ionize into ions and electrons, and the electrons emitted from the target electrode, due to the effect of the magnetic field, it will form plasma (with high density) near the cathode. Ar ions accelerate and bombard the target surface, and then atoms will sputter out from the target and fly to the substrate with greater kinetic energy, and then deposit in film.

What tungsten target needs to take into account is shown as follows:

(1) The purity of the film. The degree of vacuum should be better; the substrate should be cleaned.

(2) Deposition rate. If the deposition rate increases appropriately, the sputtering rate will be increased.

(3) Film thickness distribution. The film thickness should be relatively uniform.

(4) Selection of sputtering gas. Argon is usually selected as a sputtering gas.

(5) The sputtering voltage and the substrate potential. The substrate can not be suspended.

(6) Purity of tungsten target. Oxides and impurities on tungsten target surface will contaminate the purity of film.

(7) The temperature of the substrate. If the temperature is too high, it will affect the film's structure.

If you have any other question or inquiry of tunsten target,please feel free to contact us through the following methods:

Email: sales@chinatungsten.com sales@xiamentungsten.com

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

More Info: Tungsten Rhenium Wire Stranded Tungsten Wire Cleaned Tungsten Wire

sales@chinatungsten.com;

sales@chinatungsten.com;