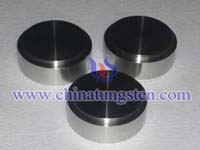

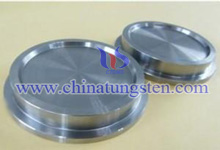

Tungsten Sputtering Target

What is tungsten sputtering target?

Tungsten sputtering target, people also call it as tungsten target, its quality will directly influence the properties of film materials, so the target materials should meet the following requirements;

1. High purity. If the purity of tungsten sputtering targets is higher, sputtering effect - corrosion resistance of the film will be stronger, and its electrical and optical properties will be better. Usually, displays and other semiconductor devices for purity requirements are stricter, for example, purity of tungsten sputtering target for magnetic thin film should be higher than 99.9%;

2. High density: not less than 19.1g / cm³;

3. Grain size should be small. Usually, the order of grains is from μm to mm, for the same composition of target materials, the rate of fine grain size of sputtering targets faster than the coarse grains;

4. Impurity content should be low. Target materials act as a cathode and the main pollution sources of sputtering target is from the pores, such as, water, oxygen, and solids impurities. The lower the impurity content, the higher the purity;

5. The composition and organization structure should be uniform.

Types of target

Classification by component, the target can be divided into pure metal target, alloy target and ceramic target.

Target types in detail can be seen as below

| Species | Composition |

| Pure metal | W (tungsten), Mo (molybdenum), Ni (Nickel), Ti (titanium), Al (aluminum), Ag (silver), Si (silicon), In (indium), Sn (tin) and so on |

| Alloy | W-Cu (copper tungsten alloy), Ag-W (silver-tungsten alloy), Cu- Ni (copper-nickel alloy), Mo- Al (Mo aluminum) and so on |

| Ceramic | ITO target [InO (indium oxide), SnO (tin oxide)], NiO (nickel oxide), WO3 (tungsten trioxide), TiN (titanium nitride), SiO (silicon monoxide), FeO (iron oxide), SiC (silicon carbide), ZnO (zinc oxide), TiN (titanium nitride), MgO (magnesium oxide), SiN (silicon nitride), CrO (chromium oxide), ZnS (zinc sulfide), SiO2 (silicon dioxide) , AlN (aluminum nitride), etc. |

Production process:

Raw materials → IF(Intermediate Frequency) induction sintering → hot rolling → cold rolling → annealing → cutting → machining→ tungsten target

If you have any other question or inquiry of tunsten target,please feel free to contact us through the following methods:

Email: sales@chinatungsten.com sales@xiamentungsten.com

Tel.: +86 592 5129696/86 592 5129595

Fax: +86 592 5129797

More Info: Tungsten Rhenium Wire Stranded Tungsten Wire Cleaned Tungsten Wire

sales@chinatungsten.com;

sales@chinatungsten.com;